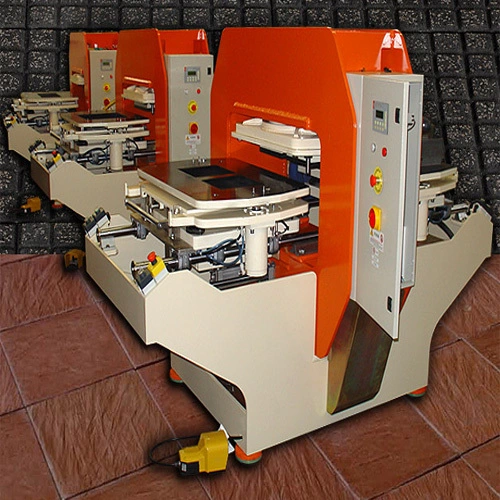

MM400-3 Encaustic tile machine

MM400-3 encaustic tile machines are the most simple and economical presses. They have one or two mould moving in line. The pressing, as well as the demoulding of the tiles are made in the central station. In the lateral stations the material is poured, then vibrated to spread it evenly and to eliminate the air bubbles that generate in the mixture.

The pressing powers go from 100 to 150 ton. The sizes are 250x250mm, 300x300mm, 400x400mm,etc. The face-layer is made of wet conrete which can be added with pigment. The bottom-layer is made of semi-dry materials. The thickness of the tiles ranges from 25 to 80mm.

Commonly, the complete production line includes the mixer, cement tile press, polishing machine, etc.

Machine Dimension: 2300X1450X1700

For tiles: 400x400, 330x330, 300x300, 250x250 and 200x200mm

Packing and delivery: Wooden box; 25 days since confirming the order.

Product Technical Data

For cement-based floor tiles, paver, wall tiles, raised floor tiles, etc.

|

Model |

MM400-3 |

Pressure |

100-150T (customized pressure is available) |

|

Power |

5.5 kw |

Weight |

2.5 Tons |

|

Production |

2-3 pcs/min |

Dimension |

2300X1450X1700 |

|

Max.mold size |

400X400 |

Hydraulic system |

Japan or Taiwan brand |

|

Electrical system |

Japan or Taiwan brand |

Product Features

Service

Offering pre-sale and after-sale service

Offering layout of the machines per the clients' workshop

Offering overseas installation service and training program

2-yead warranty

Payment: T/T or L/C

FAQ

For more informaiton, please contact us.